Aluminum Window Solutions for Commercial and Project Procurement

- Share

- publisher

- BLOSSOM CHEER

- Issue Time

- Dec 25,2025

Summary

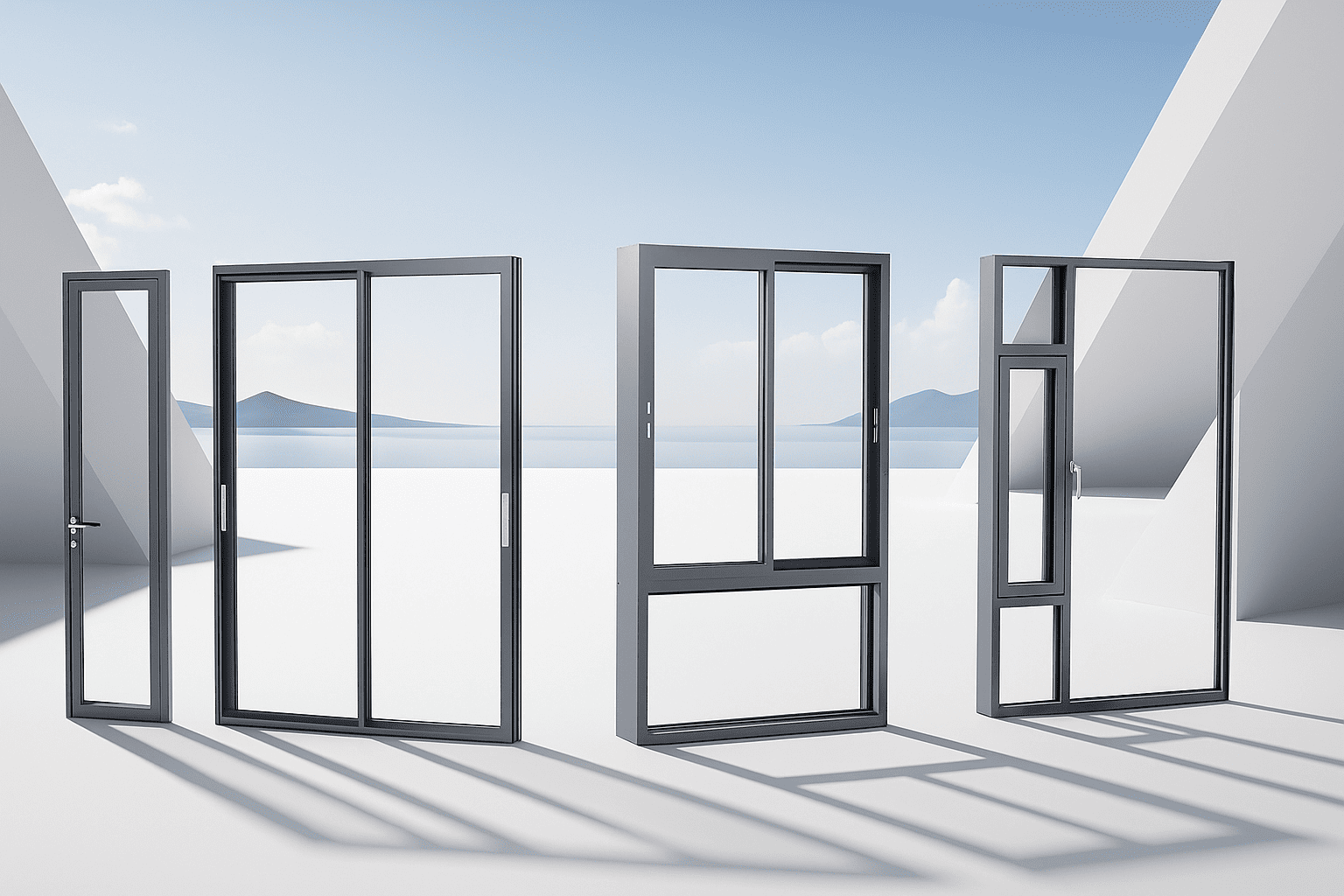

For developers, architects, and procurement specialists, the selection of window systems is a critical factor in a building's energy performance, structural integrity, and long-term maintenance costs. Modern aluminium window frames offer a superior combination of durability, design flexibility, and thermal efficiency, making them the standard choice for large-scale commercial and residential projects.

The Technical Superiority of Aluminum Window Frames for Projects

Aluminium window frames are technically superior for project use due to their inherent strength, which allows for larger glass areas and narrower sightlines, and their durability, which minimizes long-term maintenance costs. When paired with a high-quality thermal break, they provide excellent energy performance suitable for diverse climates.

The robust nature of aluminium window frames is essential for meeting the stringent demands of commercial construction:

•Structural Integrity: Aluminum's strength-to-weight ratio allows it to withstand high wind loads and support heavy, multi-pane insulated glass units (IGUs), which is crucial for high-rise or exposed locations.

•Longevity: Unlike other materials, aluminum does not warp, rot, or rust, ensuring that the window system maintains its performance and aesthetic integrity over the building's lifespan.

•Design Flexibility: The material can be extruded into complex profiles, enabling the creation of specialized systems like aluminum casement windows and large fixed glazing units, all under a single, cohesive aesthetic.

How Do Aluminum Casement Windows Compare to Other Project Solutions?

Aluminum casement windows offer exceptional performance ratings for air and water tightness due to their compression seal mechanism, making them ideal for projects in severe weather zones or those requiring superior energy efficiency. Other solutions, such as sliding windows, prioritize ventilation and ease of operation over maximum sealing performance.

The choice between window types often depends on the project's specific functional requirements:

1. Aluminum Casement Windows

•Performance: The sash presses tightly against the frame when closed, creating a continuous compression seal. This results in superior air and water resistance, making them the preferred choice for energy-conscious designs.

•Application: Ideal for residential towers, hotels, and commercial buildings where thermal performance and sound reduction are paramount.

2. Aluminum Sliding Windows

•Performance: Utilize brush or fin seals, which are less effective than compression seals. While offering excellent ventilation, their air and water infiltration ratings are typically lower than casement systems.

•Application: Suitable for areas where frequent, easy operation is prioritized, such as ground-floor offices or internal partitions.

3. Aluminum Storm Windows and Awnings

•Aluminum Storm Windows: These are secondary aluminium window frames installed over existing windows. They are primarily used in aluminum replacement windows projects to improve insulation and reduce air leakage without replacing the primary window unit.

•Metal Window Awning: A metal window awning (or canopy) is a fixed or operable external structure designed to manage solar heat gain and protect the window opening from rain. Integrating a metal window awning into the facade design is a passive strategy for reducing cooling loads in sunny climates.

| Window Type | Primary Sealing Mechanism | Air/Water Tightness | Ideal Project Use |

| Casement | Compression Seal | Excellent (Highest Rating) | High-rise, Severe Weather, Energy-Efficient |

| Sliding | Brush/Fin Seal | Good (Lower Rating) | High Ventilation, Easy Operation |

| Fixed | Continuous Seal | Excellent (Highest Rating) | Maximum Light, Non-Operable Areas |

Essential Considerations for Custom Window Order and Replacement Projects

Successful execution of a custom window order or aluminum replacement windows project hinges on meticulous pre-production measurement, clear specification of performance standards, and a robust quality control process that accounts for batch consistency across the entire order volume.

1. Precision in Custom Window Order Specifications

When dealing with a large custom window order, even minor dimensional errors can lead to significant on-site delays and cost overruns.

•Rough Opening Verification: We strongly advise project teams to provide final, verified rough opening measurements. Our technical team uses these to generate precise shop drawings for every aluminium window frames unit, ensuring a perfect fit.

•Hardware Consistency: For aluminum casement windows, specifying a consistent, heavy-duty hardware package (e.g., multi-point locking systems) across all units is essential for long-term operational reliability and simplified maintenance.

2. Aluminum Replacement Windows: Retrofit Strategy

For renovation or refurbishment projects utilizing aluminum replacement windows, the strategy shifts from new construction to seamless integration.•Sub-Frame Assessment: The condition of the existing sub-frame must be assessed. Our replacement systems are designed to minimize disruption while maximizing the performance gains (e.g., improved U-factor and SHGC).

•Integration with Existing Facade: Consideration must be given to the interface between the new aluminium window frames and the existing exterior cladding, especially when integrating features like a metal window awning.

Integrating Technical Support and OEM Capabilities into Your Supply Chain

BLOSSOM CHEER is structured to serve the complex supply chain demands of B2B clients, offering a partnership that extends beyond manufacturing.

OEM/ODM and Technical Documentation

We support full OEM/ODM customization, allowing you to leverage our production capacity and quality control under your own brand specifications. This includes:

•Technical File Provision: Supplying all necessary technical documentation, including material specifications, structural calculations, and certified test reports for all aluminum casement windows and other systems.

•Custom Window Order Support: Providing free, detailed Auto-CAD shop drawings for every custom window order, ensuring precise alignment with your architectural plans before production commences.

Installation and Project Support

Our project support team provides technical consultation to your on-site installation teams, ensuring that the high-performance characteristics of the aluminium window frames are maintained during installation. We offer remote guidance on flashing, sealing, and hardware adjustment.

Partner with BLOSSOM CHEER

The successful execution of a large-scale project relies on the technical precision of the products and the reliability of the manufacturer. By addressing these procurement-stage questions early, you mitigate risk and ensure the long-term performance of your building envelope.

To discuss your specific project requirements, request a technical portfolio, or inquire about our OEM/ODM capabilities for aluminum replacement windows and new construction systems, please contact our B2B project team.

Luxury Style High Quality Aluminum tilt&turn Window

High-end Customized Reinforced Aluminum Fixed Window

High-end Customized Ultra-thick Aluminum Sliding Window

Conventional aluminum alloy sliding windows offer a sturdy design, easy operation, and suit various architectural styles.